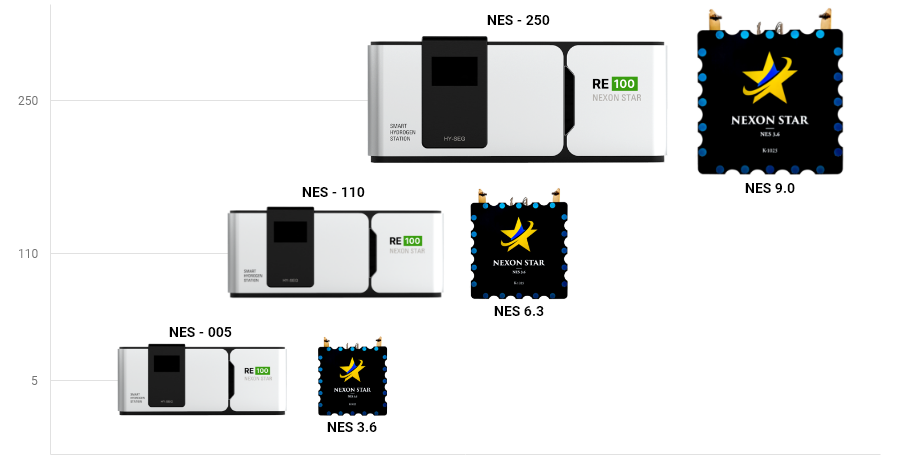

• Securing technology that can respond to load fluctuations in renewable energy (load fluctuation linked response type)

In the case of water electrolysis, a general hydrogen production method, it is dependent on the ESS Energy Storage System due to difficulties in responding to load changes in renewable energy power, but NEXON STAR

Stack is an ESS-independent water electrolysis device optimized for load fluctuations in renewable energy with an operating range of 10 to 100%.

- overshoot, undershoot Securing fast response to supply power

- Securing durability when starting and stopping repeatedly

- Reverse current prevention when stack is stopped due to load change

- Securing durability of electrode load fluctuation due to irreversible oxidation due to reverse current

- Securing stability of separation membrane to prevent gas mixing at low load

- Prevention of reduction in current efficiency due to shunt and leakage

• Securing Optimization Control Technology

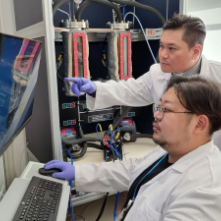

In the case of a general water electrolysis stack, it is impossible to monitor and manage each cell, so when a failure occurs, a long period of operation is stopped during checking and repairing a defective cell.

By applying patented technology that can measure and manage signals and self-developed remote terminal device, downtime can be minimized through monitoring of defective cells, notification in advance, confirmation and replacement.

-Measurement management and control of stack unit cell temperature (thermal management), voltage, current, pressure, etc.

-Self-diagnosis and early warning possible through monitoring by stack cell

• Investment and operation cost reduction, ICT-based operation management

Existing PEM water electrolysis facilities use ultrapure water for hydrogen production, so water purification facilities are essential, but Nexon Star's stack technology uses RO water that does not require ultrapure water purification facilities.

Since it is possible, it is possible to reduce the cost of hydrogen production by reducing the facility investment cost for supplying ultrapure water.

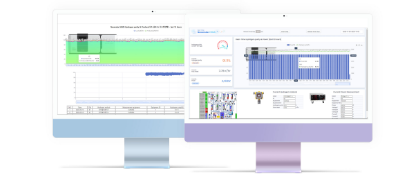

By applying the patented technology of stack design, data such as temperature, voltage, current, and pressure of the stack unit cell is collected, and self-diagnosis, predictive maintenance, and early warning information of the stack unit is provided and maintained.

Maintenance and downtime can be reduced to reduce operating expenses (OPEX).

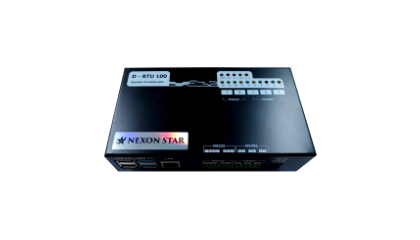

The value of various measuring points of the complex gas meter that measures the hydrogen purity and hydrogen production of the water electrolysis facility and the high-precision power meter that measures the voltage, current, and power of the facility are displayed on a remote terminal.

It is collected in real time through a device (RTU, Remote Terminal Unit) and converted into a database in the form of big data, connected to blockchain, remote monitoring and statistics/analysis through Cloud,

It provides control operation, prognostic alarm, early alarm, etc.

NEXON STAR's ICT system is an integrated operation and monitoring platform for hydrogen production, distributed data integration through remote operation, carbon credits (CDM, VCM) business that combines blockchain technology,

We aim to operate an integrated platform such as the virtual power plant (VPP) business of distributed power generation and the RE100 certification business.