• Securing patent technology for stack and water electrolysis system

• Securing original patent technology for national strategy through industry-academia-research cooperation

• Target 1/3 of selling price by 2030 by differentiating technological competitiveness and developing parts and materials

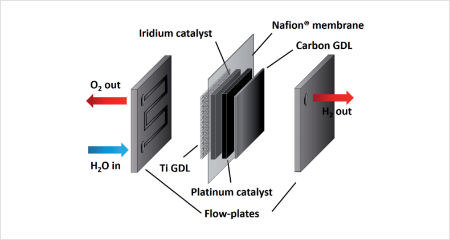

[ PEM Stack general model ]

[ PEM Stack general model ]

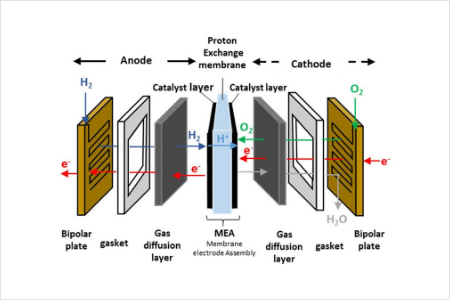

[ PEM BOP general model ]

[ PEM BOP general model ]

The leadership of the hydrogen economy is expected to be held by countries with excellent technology, such as securing patents, rather than hydrogen supply countries. It is being done in Organization for Economic Cooperation and Development (OECD) countries such as the United States, and in the case of China, it is chasing OECD countries by increasing R&D investment by 6 times compared to the previous year.

As of 2020, hydrogen economy patents are represented by 41% of fuel cells, 36% of production, 21% of storage, and 2% of distribution, and are mostly owned by Europe, Japan, the United States and Korea. According to the Korean Intellectual Property Office in 2022, the number of advanced five (IP5) patent applications in Korea, the US, Japan, China and the EU for water electrolysis technology has increased to 1,469 in the last 5 years, an increase of about 31% compared to the previous 5 years. appeared to be

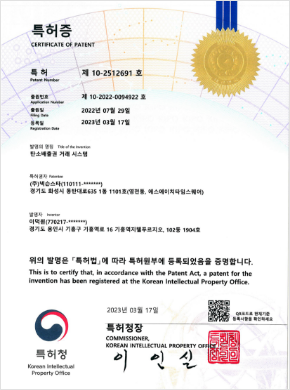

NEXON STAR began investing in renewable energy such as solar energy and fuel cells in 2018, and investing in R&D for water electrolysis stacks and water electrolysis facilities in earnest from 2021. From 2022, we are applying for 4 related water electrolysis patents and 2 water electrolysis system patents, and plan to apply for more than 10 new patents every year by expanding our R&D organization.

| Division | Patent name | Filing year | Note |

|---|---|---|---|

| Water electrolysis stack | [Security] Water electrolysis stack | 2022 | |

| [Security] Water electrolysis stack | 2023 | ||

| [Security Note] Structure Stack | 2023 | ||

| Energy self-sufficient system | Energy self-sufficient water electrolysis system | 2022 | |

| Energy self-sufficient solar power generation system | 2022 | ||

| Power generation system | Water harvesting system | 2022 | |

Platform business |

Carbon Emissions Trading System | 2022 | |

| Blockchain-based intellectual property transaction system and method | 2021 |

[ Energy self-sufficient

[ Energy self-sufficientwater electrolysis system ]

[ Energy self-sufficient solar power

[ Energy self-sufficient solar power generation system ]

[ PEM stack patent ]

[ PEM stack patent ]

[ PEM stack patent ]

[ PEM stack patent ]

[ PEM stack patent ]

[ PEM stack patent ]

[ ISO 9001 certification ]

[ ISO 9001 certification ]

[ Carbon Emissions Patent ]

[ Carbon Emissions Patent ]

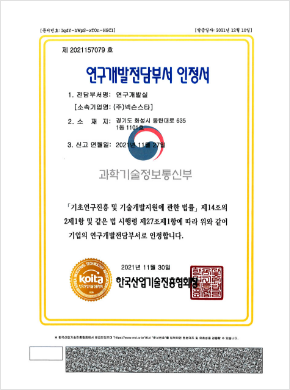

[ R&D department certificate ]

[ R&D department certificate ]